Feeding Wire

Since 1970, foreign steel plants have used pure calcium solid welding wire to treat molten steel. It has been widely used in today's world. Especially in 1990, with the rise of thin plate continuous casting technology, the advantages of pure calcium solid welding wire have been recognized by most well-known steel companies.

Category:

Keywords: nodulizing agent/inoculant/cored wire

Product Description

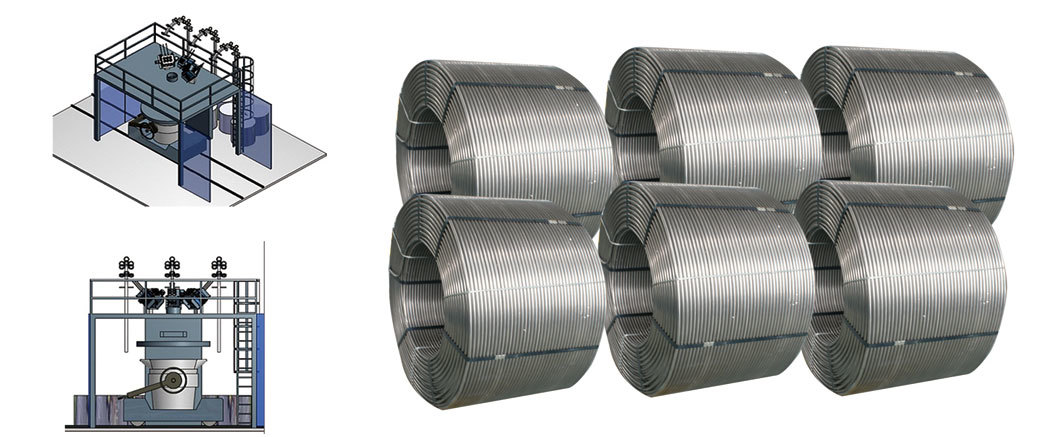

Cored wire is mainly used in secondary steelmaking

Description:

Since 1970, foreign steel plants have used pure calcium solid welding wire to treat molten steel. It has been widely used in today's world. Especially in 1990, with the rise of thin plate continuous casting technology, the advantages of pure calcium solid welding wire have been recognized by most well-known steel companies.

The cored wire is manufactured into tubular wire, wherein the calculated alloy mixture is uniquely mixed together; Then the mixed mixture is metered into the metal wire during the manufacturing process, and special alloy cores or cored wires of various diameters are produced according to the customer's requirements and demands.

Application:

The application of cored wire injection has replaced the powder injection method of fire-resistant spray gun for injection, and has proved to be an indispensable function in the secondary metallurgical treatment process. In this case, the appearance of high-speed continuous casting and the improvement of quality requirements require more strict chemical requirements, shorter process time and accurate process repeatability.

Core coated wire is a kind of powder product. According to different requirements of customers, powder elements are tightly wrapped in steel sleeves, made into circular shapes of various diameters, and packed in steel cages in the form of horizontal packaging.

The cored steel wire is deeply injected into the molten steel bath with wire feeder, eliminating problems related to low density and melting point of alloy elements, high toxicity and high affinity for oxygen and nitrogen.

Manufacturing process of core clad wire:

The cored wire is well compacted, the powder is evenly mixed, and the weight of powder per meter is controllable and uniform.

Benefits of cored wire:

Higher output, less smoke exhaust, solution to toxic and oxidizing elements, accurate and repeatable results, and reduction of gas absorption

Core clad wire products:

| Name | Model | Composition (%) | Core wire diameter (mm) |

Wire weight per meter (g) |

Weight per meter of flour (g) |

Iron powder ratio (g) |

|||||||||

| Mg | Re | Si | Ca | Ba | Sb | Al | Zr | Bi | Fe | ||||||

| Ferrite core | HTX-TA | 23-26 | 2-5 | 35-44 | 2-5 | Allowance | Φ13 | 405±10 | 235±10 | 1:1.2-1.4 | |||||

| HTX-TB | 27-31 | 2-5 | 35-44 | 2-5 | Allowance | Φ13 | 405±10 | 235±10 | 1:1.2-1.4 | ||||||

| Pearlite core | HTX-ZA | 23-26 | 2-5 | 35-44 | 2-5 | 2-5 | Allowance | Φ13 | 405±10 | 235±10 | 1:1.2-1.4 | ||||

| HTX-ZB | 27-31 | 2-5 | 35-44 | 2-5 | 2-5 | Allowance | Φ13 | 405±10 | 235±10 | 1:1.2-1.4 | |||||

| Vermicular core | HTX-R | 3-10 | 18-25 | 35-44 | 2-5 | 0.5-2 | Allowance | Φ13 | 470±10 | 300±10 | 1:1.7-1.8 | ||||

| Inoculating core wire | HTX-Y | 65-70 | 1.5-2.5 | 4-6 | Allowance | Φ13 | 440±10 | 270±10 | 1:1.6-1.7 | ||||||

| Carbon core wire | Graphitization | C≥98% | S≤0.03% | Φ13 | ≥140g/m | ||||||||||

| Petroleum coke | C≥98% | S≤0.5% | Φ13 | ≥140g/m | |||||||||||

| Deoxidized core | Calcium silicate | 55 | 30 | Φ13 | ≥200g/m | ||||||||||

| Aluminum steel | Al≥99.9% | Φ95 Φ12 | |||||||||||||

| Barium calcium silicate | 50-55 | 12-14 | 13-15 | Φ13 | ≥200g/m | ||||||||||

Related

Feedback